1.Single line light source designed,no flare

2.Can be designed as single end input voltage,safe in use

3.3000 hours lighting decay less than 1%.

4.Aluminum back cover and Aluminium PCB assure much better heat dissipatio,thus longer life span for the LED

5.Designed long life span to 50000 hours,can be used for 24 hours working time site.

There are total 6 models available regarding T8 150CM LED Tubes

The model with "F" means frosted cover

Without "F" means clear cover

Model No Dimensions Wattage Input Voltage Initial Lumens CCT Ra Cover Lighting Angle Life Span

(CM) (W) (V) (LM) (K) (Degree) (Hrs)

SL-T8-150CM-144CW-F 150*2.6 22/25 85~265 2310 5500~6000 80 Frosted 120 50,000

SL-T8-150CM-144NW-F 150*2.6 22/25 85~265 2200 4000~4500 80 Frosted 120 50,000

SL-T8-150CM-144WW-F 150*2.6 22/25 85~265 2090 2800~3300 80 Frosted 120 50,000

SL-T8-150CM-144CW 150*2.6 22/25 85~265 2310 5500~6000 80 Clear 120 50,000

SL-T8-150CM-144NW 150*2.6 22/25 85~265 2200 4000~4500 80 Clear 120 50,000

SL-T8-120CM-144WW 120*2.6 22/25 85~265 2090 2800~3300 80 Clear 120 50,000

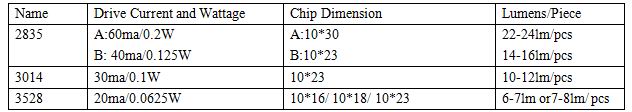

What is SMD2835?the differences between 2835 and 3014,3528

2835, 3014 and 3528 are three packaging process based on Epistar and similar dimension chips.

Generally speaking, SMD2835 LED tube is newer and more advanced than 3528. Because 2835 has more effective thermal dissipation system, specifically, a larger heat sink than 3014 on the back, and 3528 has no back heat sink at all, therefore 2835 is able to take higher current and generates more luminous flux.

The form below is the common spec of these LED solutions in these days. The data is based on June, 2013.

Why Smooth choose SMD2835 as light source?

1.Larger chip, the better

Taking 3528 for example, manufacturer could use 10*16, 10*18 or 10*23 chip to make the LED, all can be driven by 20ma, three plans get different luminous flux. Because smaller chip would generate more heat while being driven by same current as the larger chip, it also has shorter longevity and worse quality. However, for most of lamp buyers it is almost impossible to know what brand and dimension of the chip is really being used, the only way is to conclude it from the lamp’s optical performance test.

2.A controversial trick

Higher drive current will make more luminous flux to one chip, and also more heat. 3528, 3014 and 2835 all use 10*23mil chip, but the drive current are different .It is controversial that because 3014 and 2835 have large heat sink, one chip in these packagings could be driven by higher current. However this has become the most popular design.

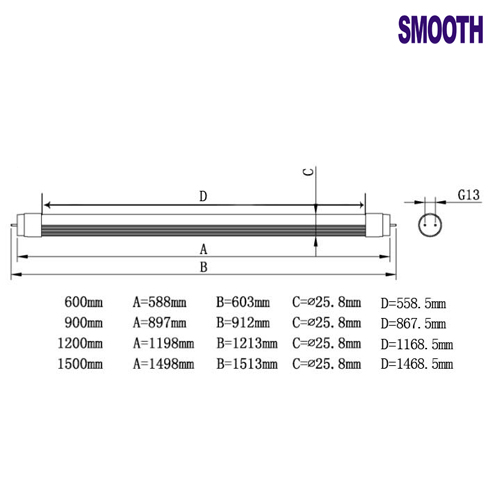

T8 150CM 22W LED tubes dimensions:

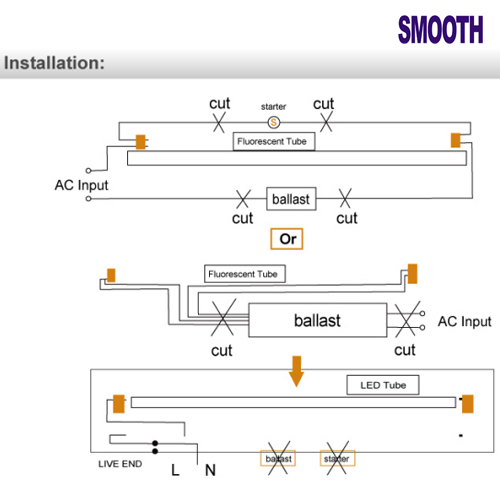

T8 150CM 22W LED tubes installation:

T8 150CM 22W LED tubes applications:

Factory lighting

office lighting

fluorescent replacement

shopping mall lighting

Case:

Follow Us on Facebook

Follow Us on Facebook  Follow Us on Twitter

Follow Us on Twitter  Follow Us on Linkedin

Follow Us on Linkedin  Watch Us on Youtube

Watch Us on Youtube  See Us on Pinterest

See Us on Pinterest